Automated Drilling Machine

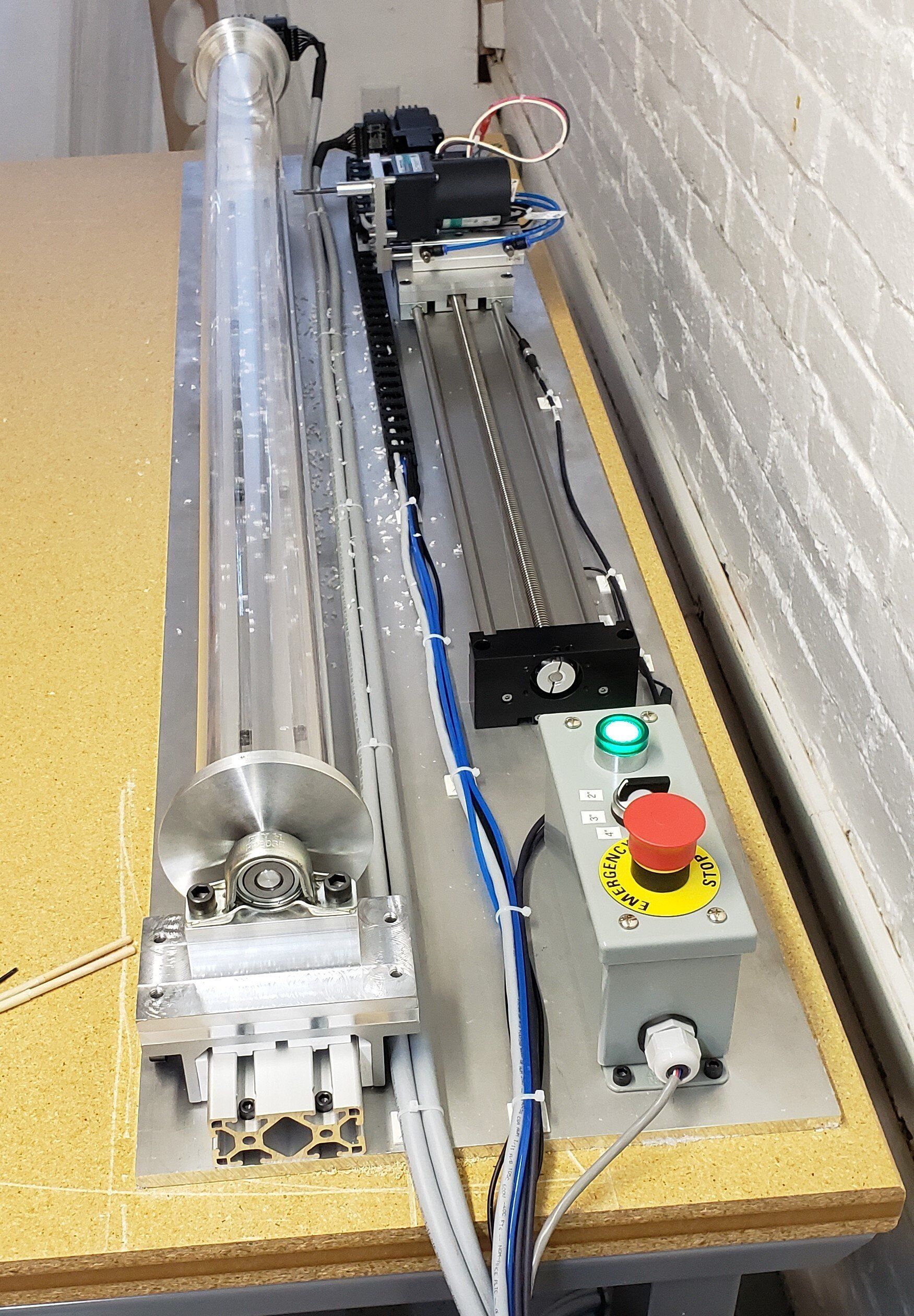

UPDATE: The Automated Drilling machine has been completed and entered service for Rainstick Dreams. Through automation, production increased by approximately 55% over the previous manual process. This machine has reduced employee fatigue and increased product quality.

Some minor design changes had to be made from the initial design discussed below. The end stops were designed to be able to hold all 3 styles of tubes without having to change out any parts. The only part of the machine that is required to be swapped out is the drill bit chuck. The smallest sized tube uses a much smaller drill bit than the other two tube sizes.

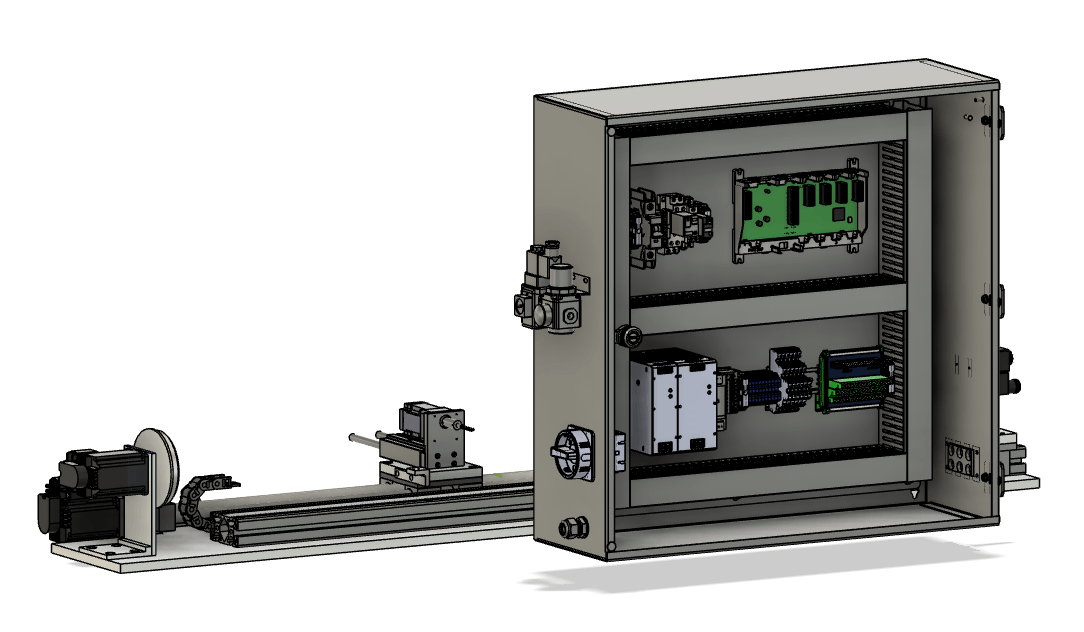

This PLC based automated drilling machine is being built for a small company called Rainstick Dreams. The owner of Rainstick Dreams expressed interest in speeding up their manufacturing process, and allowing them to work on other aspects of the process while the tubes are being drilled.

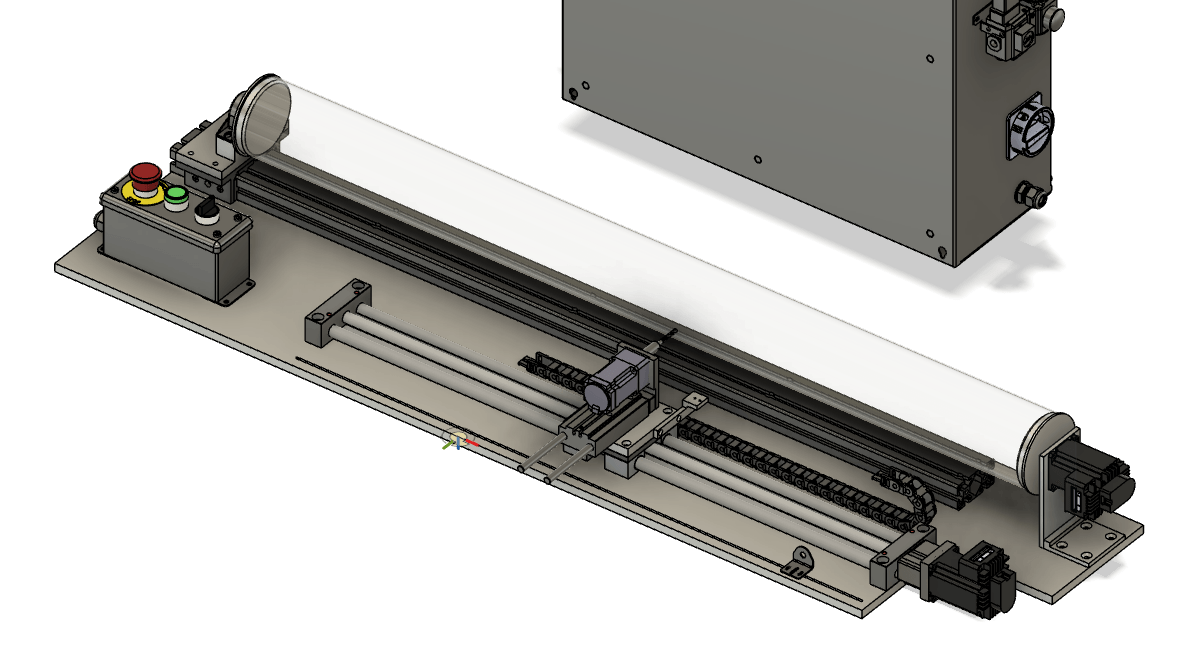

The company manufactures a variety of sizes of rain sticks which means this machine needs to be versatile and allow for quick change overs. An 80/20 frame is being used with a sleeve bearing and hand clamp to allow for quick load and unload of the tubes. Additionally, all rotating parts are able to be swapped out with a simple set screw. This will minimize setup time when switching between different tube sizes, diameter and length.

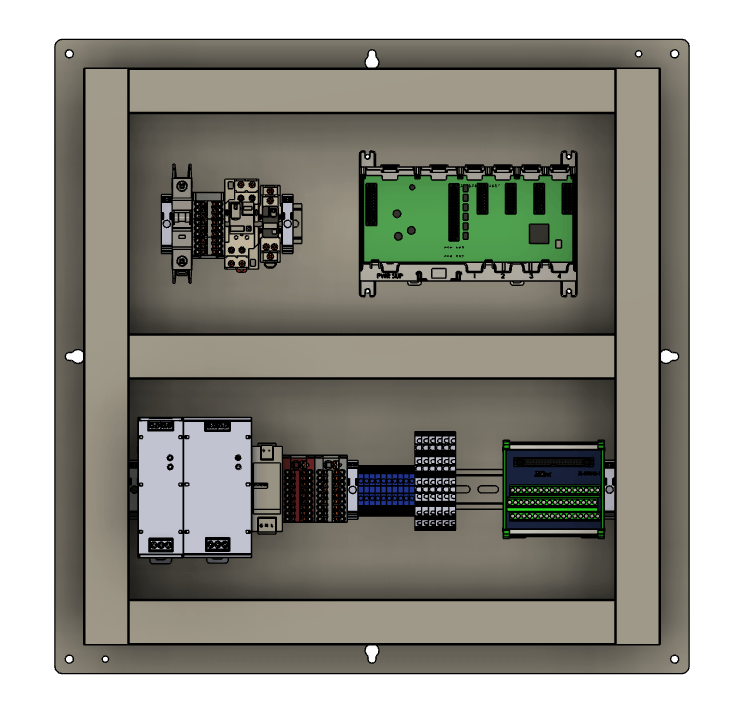

The motion control section of the machine is PLC, High Speed Output driven and connected to NEMA 23 integrated stepper drive/motors. The stepper motors were chosen due to their small size and ability to be driven by 24VDC. By using the integrated drive/motor it allows the electrical enclosure to be smaller and take up less floor space.

The drill section of the machine posed the greatest issue. To keep the machine foot print small a small 120VAC motor is being used. The motor is mounted on an air cylinder. The air cylinder will contain multiple position sensors to allow the cylinder end of stroke position to be changed based on the size tube being drilled.

The machine is currently in the mechanical development stage and will be entering the machining and programming phase soon.